Introduction of GEOMET process

Introduction of GEOMET process

As the environmental issues become increasingly serious, laws and regulations are formulated to enhance the control of hazardous substances in the world. In particular, the Hexavalent chromium compounds used for a long time as an effective means for surface rust prevention have been restricted by environmental regulations in western countries. Under such circumstance, the new Zn-Al anticorrosive coating processes without chromium (e.g. GEOMET, MAGNI, ZINTEK and DELTA) have been developed after years of research and development.

GEOMET process

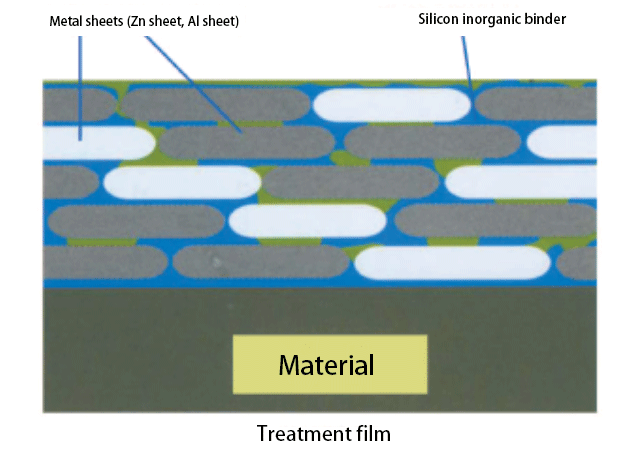

GEOMET film has a color of matte metal. Its structure consists of overlapped

metal sheets combined together with special inorganic binder.

As the thickness of film is only 8µm, it can be a good fit with nuts and screws.

2C2B is a standard process.

Feature 1: not worrying about environmental pollution

It completely contains no chromium compound during treatment and coating, and no hazardous substance according to relevant laws and regulations, which is a friendly surface treatment for natural environment and operating environment.

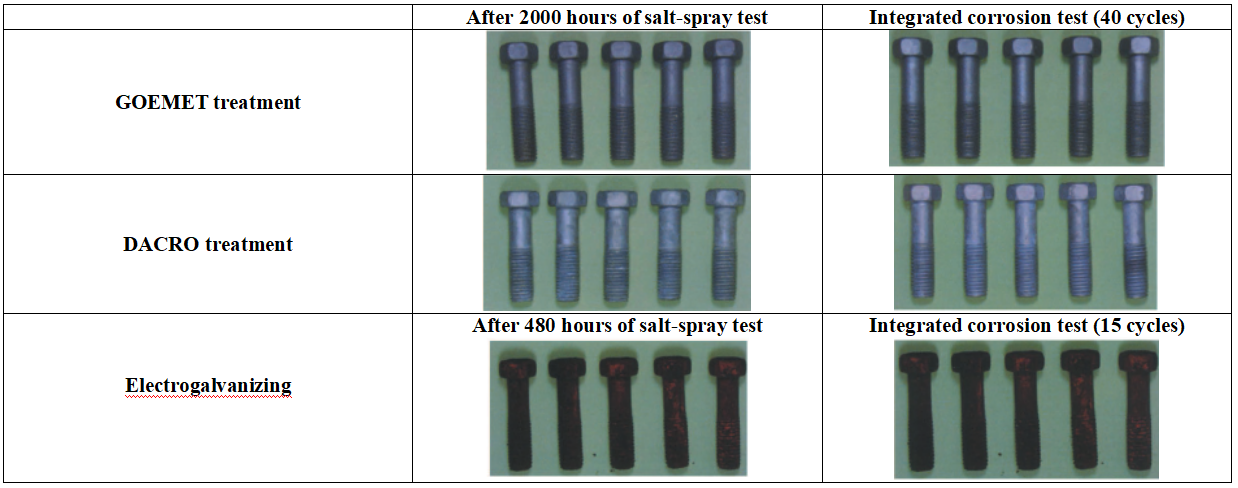

Feature 2: Excellent corrosion resistance in the salt spray test and periodically repeated test

The corrosion resistance of products in the salt spray test and periodically repeated test has particularly superior rust resistance.

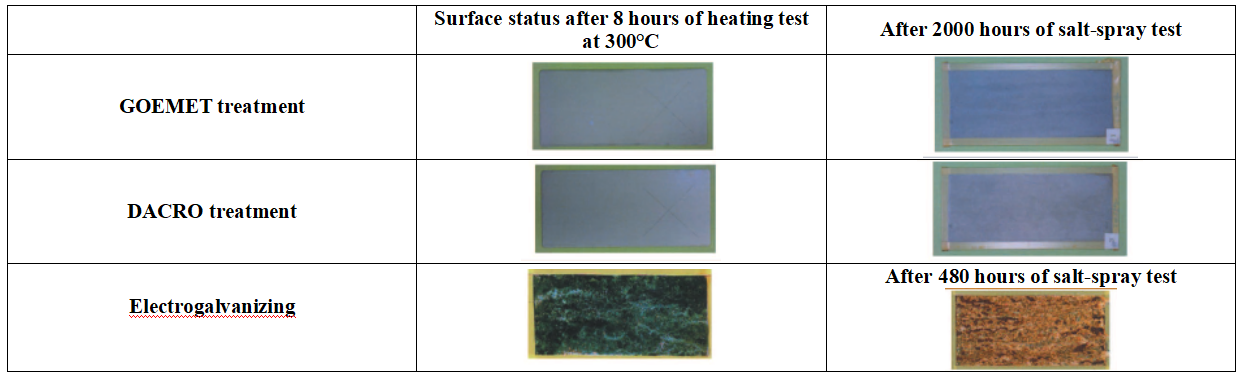

Feature 3: Excellent heat and corrosion resistance

GEOMET anticorrosive coating treatment is a surface treatment process that contains no crystal water and organic resin that would reduce heat resistance, whose layer can resist high temperature for a long time. The surface layer of electro galvanizing (colored plating) will begin to deteriorate at about 100°C, and the change in surface structure will make the corrosion resistance sharply decrease.

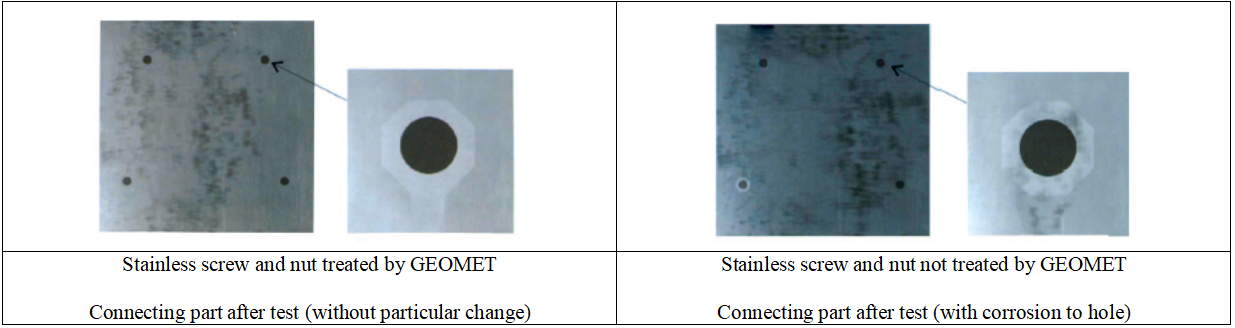

Feature 4: Prevention of dissimilar metal contact corrosion with aluminum

Test example: dissimilar metal contact corrosion test between aluminum board and stainless steel screw

Test sample:

Stainless screws and nuts that are treated and not treated by Zn-Al anticorrosive coating

Auxiliary materials

Aluminum board JIS.H.4000 5.0x70x150mm

Connecting torque:

60kgf cm

Test condition:

Different stainless screws are connected with the aluminum board with the torque above and the corrosion condition is confirmed after 3000 hours salt-spray test

Feature 5: Good adhesion

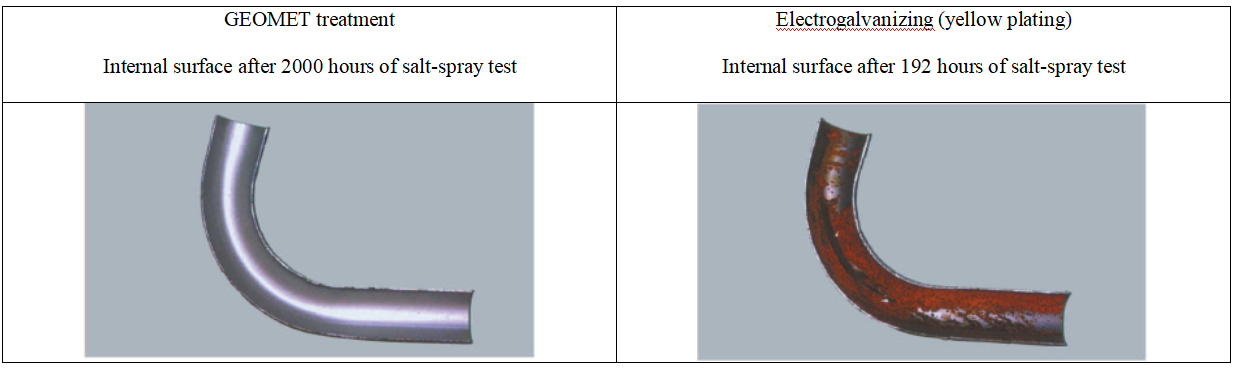

The internal surface of the GEOMET treated pipe is also plastered with anticorrosive coating for excellent rust prevention, however, basically the internal surface of pipe cannot be treated by electrogalvanizing.

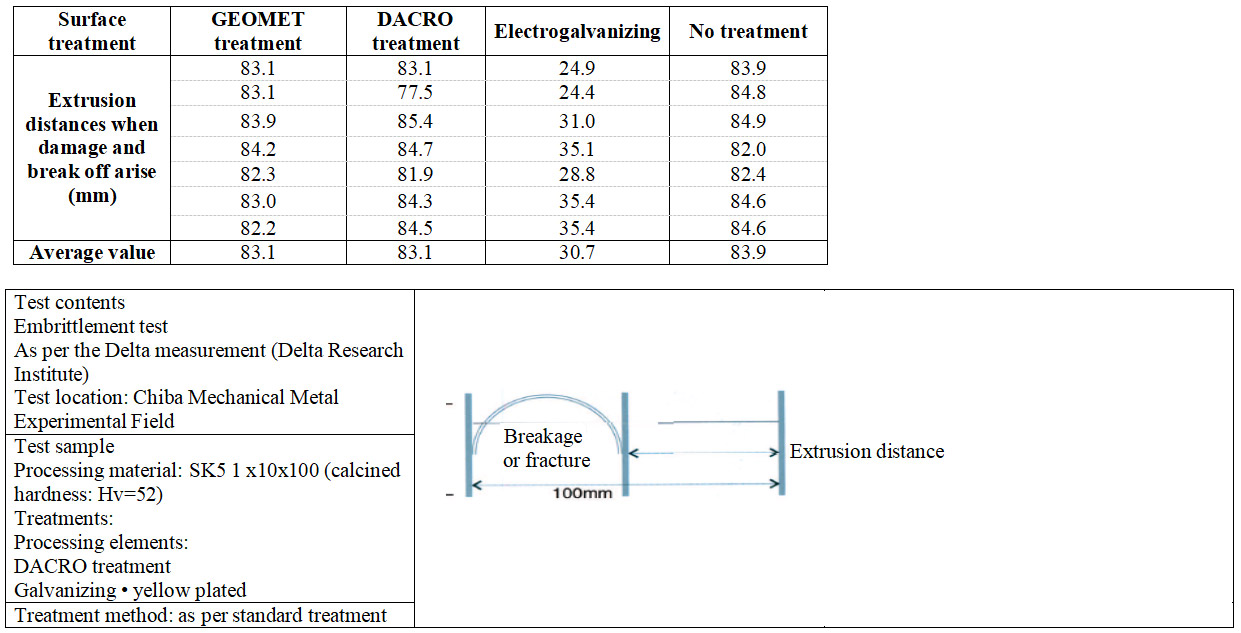

Feature 6: No hydrogen embrittlement

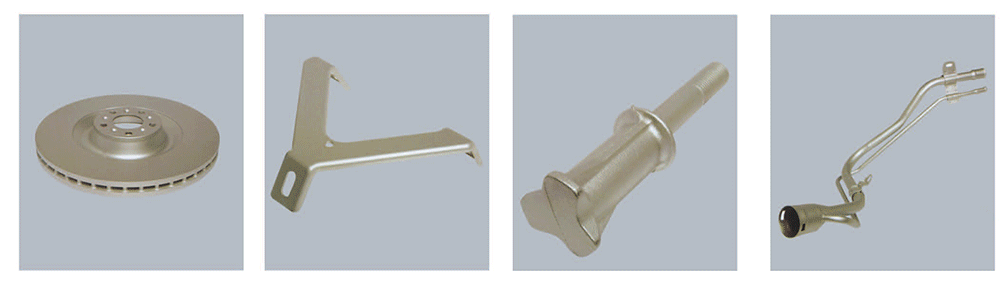

Feature 7: Treatment for all kinds of metals

In addition to iron and cast iron, GEOMET can also be used for stainless steel, aluminum, powder metallurgy materials for wide applications, and a combination of GEOMET processes with different characteristics can achieve special effect that many previous treatments cannot.achieve